US Steel is on the hunt for a site for a new $3 billion, 3 million short ton/year flat-rolled minimill, the company says.

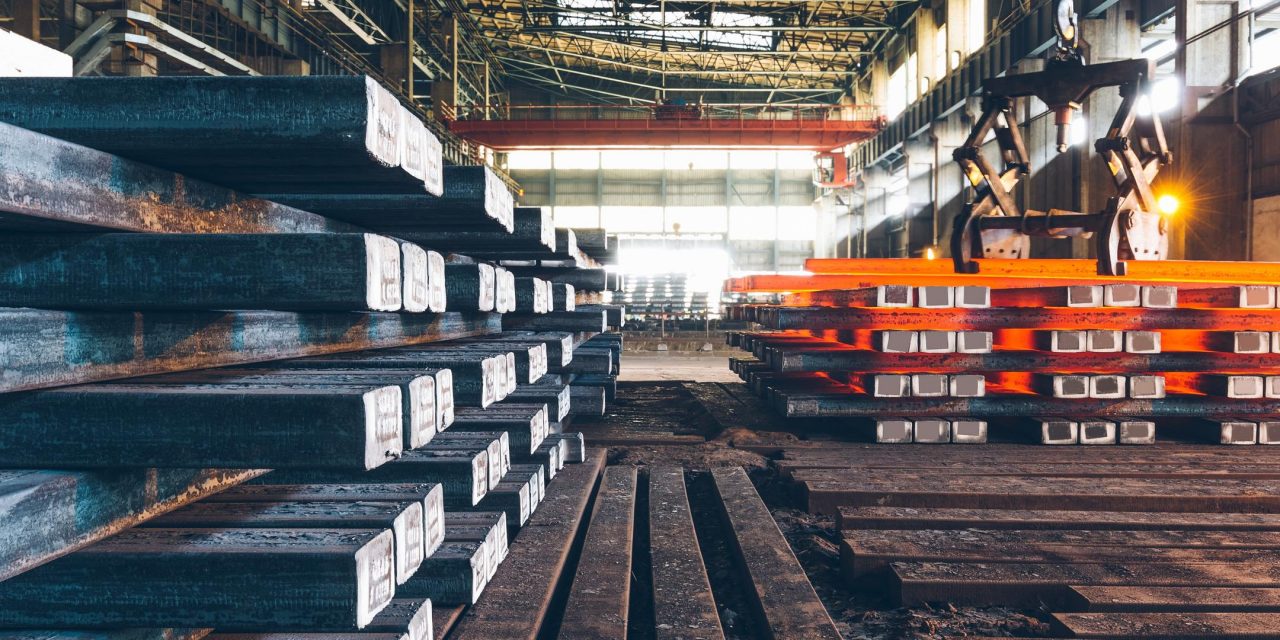

The planned minimill will run two electric arc furnaces. US Steel has only recently – but rapidly – entered the minimill arena via its Fairfield, Alabama, project and its acquisition of Arkansas’ Big River Steel, Kallanish notes.

Moving into the EAF arena is part of the company’s so-called Best for All decarbonisation strategy. The company aims to have net zero emissions by 2050.

“We already own and operate the most advanced and sustainable mini mill in the United States. Now we plan to expand this competitive advantage by continuing to combine our research and development and product innovation, deep customer relationships, and low-cost iron ore with additional mini mill steelmaking technology to create long-term value for our investors,” says ceo David Burritt.

Taking into account the complex site-selection process, the company plans to begin construction in the first half of 2022 with production slated for 2024.

“Our goal is to build capability to get better, not bigger. By accelerating our transition to more efficient mini mill steelmaking, we expect to continue differentiating ourselves versus less efficient capacity while improving our through-cycle profitability and lowering our capital and carbon intensity,” Burritt adds.

Dan Hilliard USA